The Best Supply Chain Management Software

We’ve reviewed the top supply chain management software for companies of all sizes, from small eCommerce retailers to enterprise distributors. These platforms help businesses predict demand, optimize inventory, and forecast sales.

- Dynamic eCommerce and in-store experiences

- Predictive scenario planning

- Supply chain planning with transportation and logistics

- Effectively monitors precisely-defined KPIs

- Hyperblock™ modeling and calculation engine

- Fast reactions to demand changes

- Add custom fields to enhance reporting

- In-depth shipment details

- Integration with shipping carriers

Supply chain management software streamlines the product journey from supplier through manufacturing and sales to the consumer, optimizing the flow of goods, information, and finances. Here’s a rundown of our top picks based on user reviews and our internal review process.

- Blue Yonder Luminate: Best Overall

- Anaplan: Best Forecasting Tools

- Magaya: Best for Freight Forwarding

- Precoro: Best for Spend Management

- Netstock: Best Inventory Optimization

- Lumina: Best Automation Tools

- Oracle SCM Cloud: Best for NetSuite Users

- Logiwa WMS: Best for eCommerce

- Intuendi: Best AI-Powered Option

- Logility: Best for Large Manufacturers

Blue Yonder Luminate - Best Overall

Blue Yonder Luminate’s supply chain planning module helps retailers, distributors, and manufacturers optimize their forecasting processes. It includes automated scenario planning so you can be ready for any market volatility. The tool uses real time data from the system, so resource and inventory information are all up to date while planning.

The supply planning module also includes AI and machine learning functionalities to create predictive insights. It uses historical data across your entire operation to recommend and forecast demand or inventory counts. You can use these insights to make more informed decisions or understand the current market better. This is crucial for the retail industry, as unexpected demand fluctuations can impact profitability.

The system is designed to integrate seamlessly with other enterprise systems such as ERP software, WMS software, and TMS software. This interoperability ensures data flows smoothly across different parts of the organization, improving visibility and coordination.

Blue Yonder Luminate is best for large-sized to enterprise companies managing complex supply chain operations and high data volumes. Smaller eCommerce companies with simpler workflows may want to consider Logiwa WMS as an alternative.

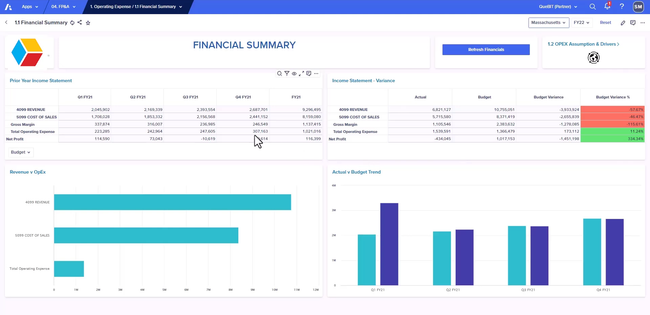

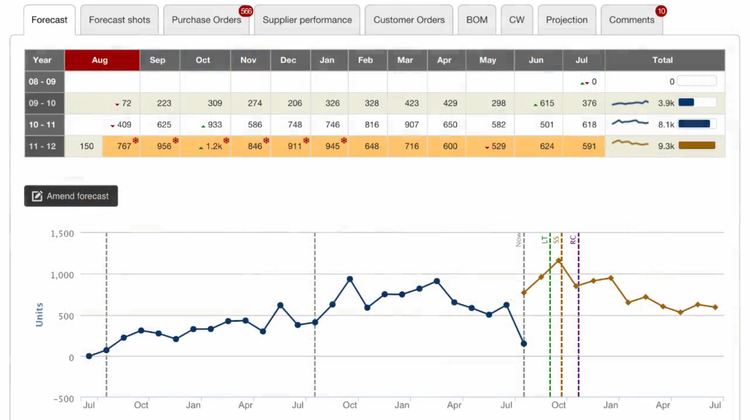

Anaplan - Best Forecasting Tools

Anaplan’s advanced analytics capabilities, including predictive analytics and machine learning, enhance the accuracy of forecasts. Additionally, the platform supports scenario planning, allowing businesses to evaluate the potential impacts of various scenarios.

This supply chain software is highly customizable, enabling businesses to tailor their forecasting models to their specific needs. This flexibility allows companies to incorporate unique business rules, workflows, and scenarios into their forecasting processes. Anaplan can handle high volumes of data and complex models without negatively impacting performance. This scalability is vital for large enterprises or businesses with complex supply chains that need to process and analyze large datasets to generate accurate forecasts.

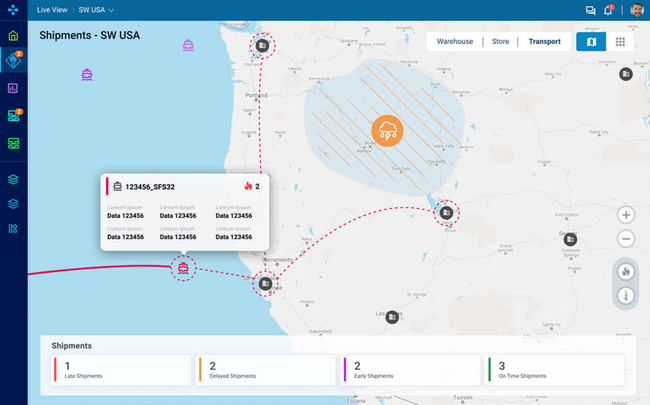

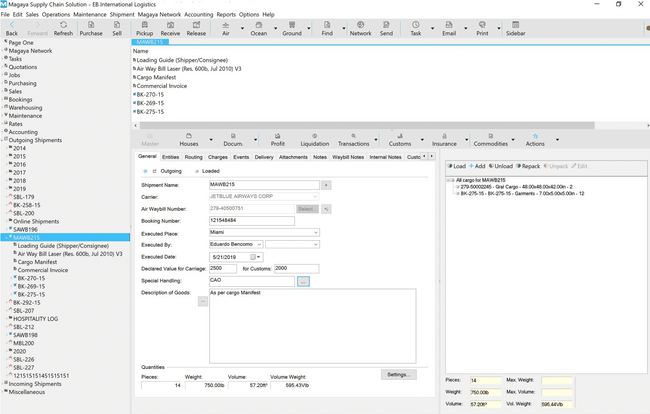

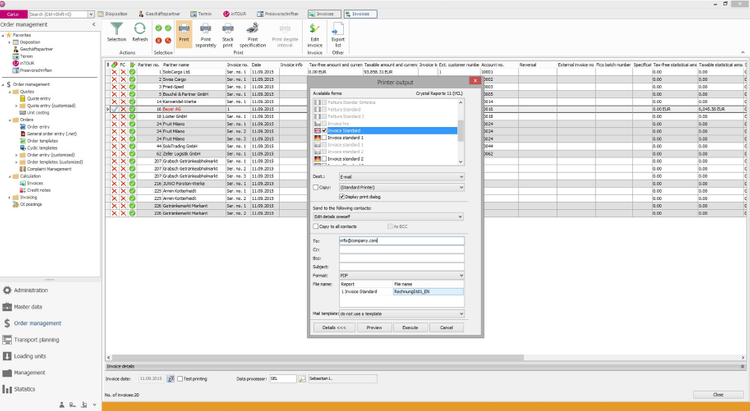

Magaya - Best for Freight Forwarding

Magaya effectively manages the logistics process, from quoting to billing. Magaya allows users to quickly generate accurate quotes for customers based on real-time rates, including carrier rates, surcharges, and other fees. This feature simplifies the quoting process and helps secure businesses more efficiently. Additionally, users can manage all types of shipments, including air, ocean, and ground, within a single platform. That includes creating shipments, consolidating cargo, managing all related documentation, and providing a full overview of each shipment’s status.

This supply chain management tool offers integration with various carriers. That way, it’s easier to book shipments directly within the software and access carrier schedules. This integration simplifies the booking process and improves visibility throughout the transportation lifecycle. The software includes tools for managing customs compliance, including generating necessary documentation and electronic filing with customs authorities. This feature is crucial for ensuring smooth cross-border shipments and avoiding delays or penalties.

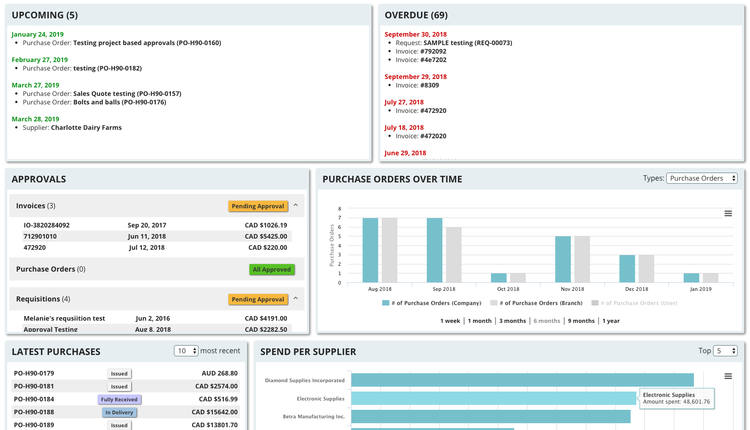

Precoro - Best for Spend Management

Precoro includes strong spend management capabilities, including approval workflows, real-time budgets and reports, requisition, ordering, and billing. These features help businesses save time, reduce costs, monitor overall spending, and make more informed decisions on expenditures and planning. Its real-time reporting allows for immediate visibility into cost centers and budget allocations, facilitating adjustments to procurement processes based on accurate and up-to-date information.

Precoro leverages analytics to streamline purchasing processes, offering detailed approval rules for operational efficiency and record-keeping. Users have clear visibility into the approval chain and transaction details. Precoro’s cloud-based nature allows for mobile approvals, ensuring that critical decisions can be made anytime.

Netstock - Best Inventory Optimization

Netstock is our top pick for advanced inventory control and optimization. One of its strengths is its demand forecasting capabilities. It uses historical sales data and advanced algorithms to predict future inventory needs, helping companies maintain optimal stock levels and reduce the risk of stockouts or excess inventory.

The software includes sophisticated analytics tools that provide insights into inventory performance. It can highlight issues like overstock, understock, and product obsolescence for proactive inventory control. Effective SCM often involves multiple departments and external partners. Netstock provides collaboration tools that enable seamless communication and coordination among all stakeholders involved in inventory management.

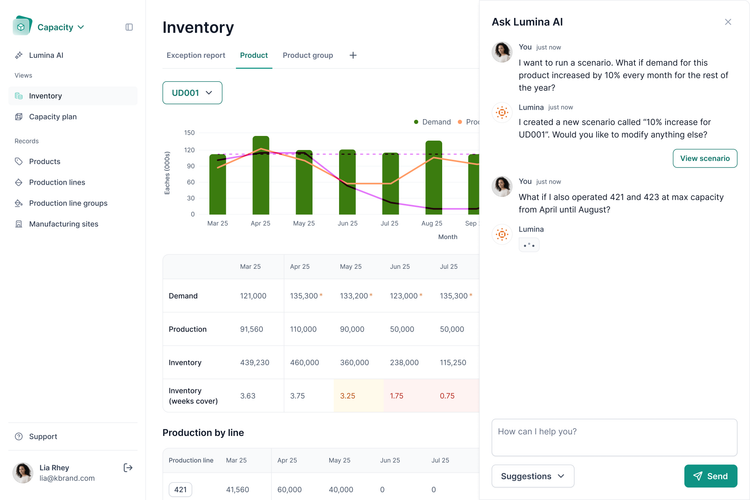

Lumina - Best Automation Tools

Lumina offers strong automation tools to streamline your processes. Specifically, you can configure one-click rules within all levels of the supply chain process, from order fulfillment workflows to automatic reorder triggers for inventory. Or, you can set up alerts and reminders that automatically send based on specific parameters. Plus, the automations don’t require coding or extensive technical knowledge, making it easy for new users.

Additionally, Lumina stands out for its modern and intuitive UI throughout the system. You can easily connect data from your other platforms, like accounting, 3PL, or eCommerce, giving you a consolidated view. And if you’re using lengthy spreadsheets, you can organize the modules to match your existing workflows, helping to reduce training time. This makes it a great option for growing businesses that require data organization without needing the complexity of a standard ERP.

Lumina was officially launched in 2024, making it the newest product on our list. The modern interface and AI automation make it an exciting new system in the supply chain market for product-based businesses with 5-50 employees. Pricing starts at $1,000/month, but you’ll need a custom quote for exact figures.

Learn more information on our Lumina product page.

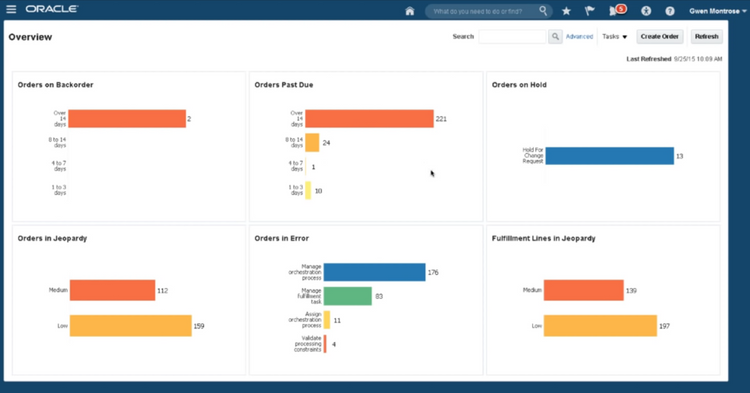

Oracle SCM Cloud - Best for NetSuite Users

Oracle acquired NetSuite in 2016, making the integration between NetSuite and Oracle SCM Cloud more seamless than with other third-party applications. This integration allows for smoother data flow and process synchronization between ERP functions provided by NetSuite and the supply chain management capabilities of Oracle SCM Cloud.

Oracle SCM Cloud offers many supply chain management functionalities, including procurement, product lifecycle management, supply chain planning, logistics, and manufacturing. This comprehensive suite can enhance NetSuite’s ERP capabilities, providing users with a more advanced solution to manage their business operations.

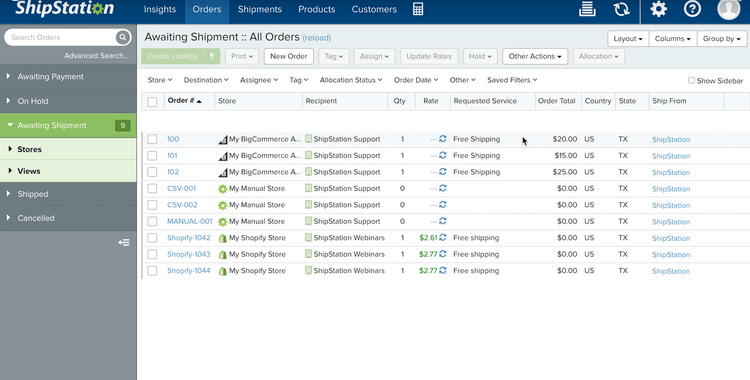

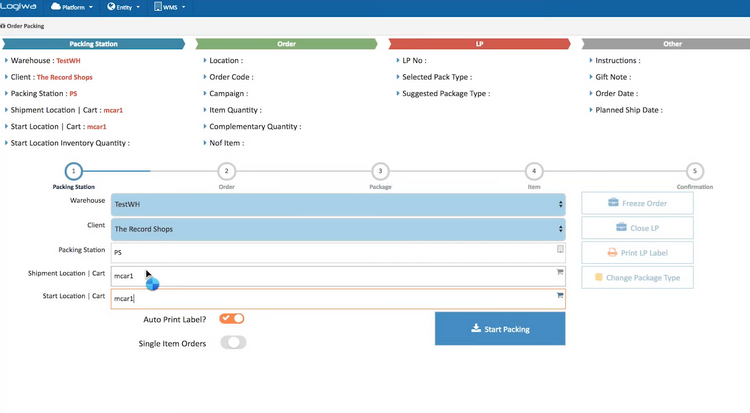

Logiwa WMS - Best for eCommerce

Logiwa has efficient warehouse management, which is crucial for eCommerce companies to process and ship orders to meet customer expectations for fast delivery. Logiwa’s warehouse management features help organize and optimize operations, from stocking and storage to picking, packing, and shipping. This reduces processing times and errors, directly impacting customer satisfaction and repeat business.

This SCM software helps eCommerce companies maintain optimal stock levels with features like demand forecasting, replenishment recommendations, and multi-location inventory management. This improves inventory turnover and reduces carrying costs. The software offers order management features, including order tracking, batch processing, and automated routing. This ensures that orders are fulfilled accurately and efficiently, enhancing customer satisfaction.

Intuendi - Best AI-Powered Option

Intuendi is effective due to its machine learning and artificial intelligence capabilities. The platform offers several forecasting methodologies, including top-down and bottom-up approaches, to best match each enterprise’s distinct requirements. Users have the flexibility to fine-tune how data influences forecasts, ensuring the system’s output is closely aligned with their operational strategies.

Such detailed customization enables companies to maintain optimal inventory levels by providing timely alerts on potential understocking or overstocking scenarios. In response to these alerts, the Intuendi AI can proactively recommend the precise inventory quantity to order, the optimal timing for these orders, and the most suitable suppliers based on delivery speed or cost-effectiveness. This proactive approach to inventory management aids businesses in optimizing their supply chain efficiency and reducing associated risks.

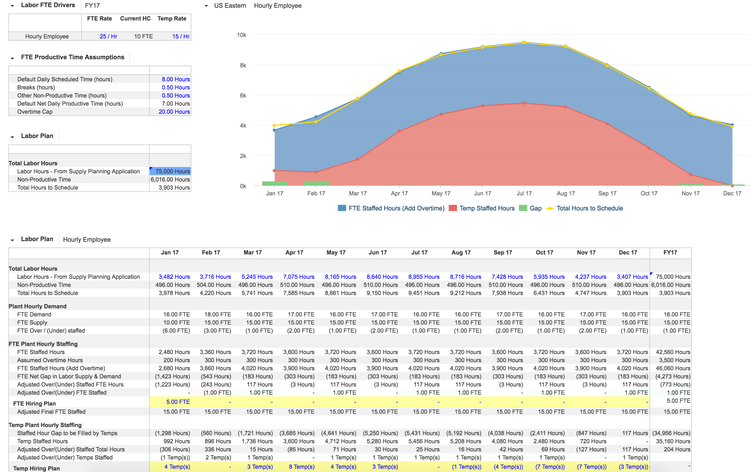

Logility - Best for Large Manufacturers

The supply optimization module in Logility keeps supply, demand, and production in sync across your entire network, from customer sites and distribution centers to supplier hubs and factory floors. This SCM software lets you run real-world simulations to test how delays and carrier constraints might impact your operations. This helps you make tweaks to your sourcing or scheduling plans before that ever becomes a problem.

Instead of treating safety stock as a fixed number, Logility uses machine learning to constantly recalculate prime inventory positions based on demand patterns and supplier reliability. With the InventoryAI+ tool, you’ll get built-in multi-echelon inventory optimization (MEIO). This lets you know where to hold stock, how much of a buffer is needed, and when to move inventory upstream or downstream. Exception-driven workflows flag only what needs attention so your team is focusing solely on high-impact decisions.

We generally recommend Logility for large manufacturers with shared production resources and fluctuating demand across different regions. While pricing isn’t publicly listed, the ability to model “what-if” scenarios is a serious advantage. You’ll respond more quickly across the supply chain, from procurement through delivery, where every delay carries a cost.

What is Supply Chain Management (SCM) Software?

Supply chain management (SCM) software helps manufacturers, logistics providers, distributors, suppliers, and retailers manage the flow of goods and services between locations as efficiently and cost-effectively as possible. Known as a type of logistics software, it assists in acquiring raw materials for a finished product delivered to a customer.

SCM software makes it possible to plan, control, and execute the supply chain processes that make the manufacturing and distribution of finished goods a reality. Taking a holistic approach to supply chain management, SCM software maximizes cost reduction opportunities in getting products provisioned from the vendor to the customer.

Considering every possible strategic or business analysis possibility, SCM software enables organizations throughout the supply chain to make informed decisions about network optimization, business partnership planning, and product lifecycle management. This is accomplished by coordinating raw materials, purchase orders, vendors, warehouse management, and distribution.

Key Features

| Feature | Description |

|---|---|

| Requisition and approvals management | Automates the collection, approval, and fulfillment of requisitions. Often linked with purchase order management systems, this feature helps employees begin acquiring the necessary goods and services to fulfill orders for customers. |

| Purchase order management | Allows you to issue orders for services and products. Tracks all key order info, including the vendor, purchase quantities, item or service purchased, delivery timeframes, payment terms, and costs. |

| Vendor management | Manages all levels of communication with vendors. Measures ship windows times, how quickly documents are submitted, effective utilization of containers, and accuracy of shipments; double checks quantity and quality of received products. |

| Supplier Management | Includes contract management, risk management, purchase order processing, supplier performance reviews, and product lifecycle management to maintain supplier relationships. |

| Demand planning | Utilizes information from the point of sale, ship-to or warehouse data, social data, or the weather to understand demand better. Sets performance benchmarks, allocates resources, and optimizes targets. |

| Sales forecasting | Uses machine learning to anticipate sales levels and aid appropriate production processes. Looks at analytics such as seasonality, historical sales, product launch dates, etc. |

| Warehouse management | Provides powerful tools to design a warehouse’s workflow, control stock, generate bills and reports, and manage yards, docks, and labor. |

| Inventory control | Keeps track of all information about the items your company builds, buys, stores, or sells. |

| Product lifecycle management | Reduces cost on product launch and meets market demands to maximize the profitable years of the product. |

Primary Benefits

Supply chain software simplifies the intricate and complex process of getting products from the supplier to the customer. With SCM software, supply chain providers can gain insight and control over every aspect of the manufacturing and distribution process, including:

- Vendor management

- Demand planning and sales forecasting

- Inventory and warehouse control

- Delivery optimization planning

Eliminate Delays That Cause Decreased Customer Satisfaction

Increased visibility and control over the supply chain makes it possible to identify potential inventory, distribution, and labor issues. SCM software can prevent delays and ensure products are delivered when promised by proactively enabling supply chain providers to respond to changes in real-time.

Identify the Vendors Offering the Most Attractive Rates

SCM software’s business intelligence capabilities can identify suppliers offering the best commodities or transportation prices.

Maintain Just-in-time Inventory and Reduce Warehousing Costs

SCM software maximizes warehouse efficiency by making just-in-time inventory management possible, ensuring goods are only received as needed. Just-in-time inventory can greatly reduce waste and decrease the cost of unnecessary storage.

Avoid Shortages and Backorders That Contribute to Lost Business

Comprehensive tools for demand planning and collaboration among multiple suppliers and distributors can prevent shortages and backorders by maintaining an accurate view of product and supply levels.

Optimize Warehousing, Requiring Less Space or Fewer Facilities

SCM software analyzes the movement of materials among warehouses and helps plan for current and future needs, enabling supply chain producers to free up space in warehouses or distribution centers.

Provide Real-Time Updates to Customers on Order Provisioning Status

Live insights offering transparency throughout the order fulfillment process are possible with SCM software, letting customers know the status of their purchase across the supply chain.

Utilize Historical Data to Feed Future Projections and Forecasting

Business intelligence and trend analysis features make it possible to manage and predict demand accurately. SCM software enables supply chain providers to make data-informed decisions about inventory and sales, potentially saving on inventory and warehousing costs and maximizing opportunities for production.

Decrease Turnaround Time

Better supply chain visibility means the location of any given item can be tracked, enabling products to be built, shipped, and delivered as quickly and accurately as possible.

Reduce Holds on the Production Line

SCM software helps coordinate and execute production and logistical operations, making it simpler to manage production lines and cut down on holdups or delays.

Types Available

Supply chain management software will affect almost every department in your organization. As such, you’ll want to find a solution that gives you the visibility you need to ensure your automated workflows and staff operate as intended.

At its core, a fully integrated SCM software will help you through product development, sales and operations planning (S&OP), procurement, production, logistics, and warehouse management.

While many SCM software solutions exist, finding the best choice for your operation doesn’t necessarily mean selecting the most popular or most extensive solution. Be sure to take time and carefully assess the different features and capabilities of any SCM software you’re considering.

Logistics Software

Sometimes used as a synonym for supply chain management software, logistics software manages the supply chain of products from their point of origin to the point of consumption via transportation, inventory, warehousing, material handling, and packaging features.

Whether your business deals with inbound logistics (linear flow of raw materials from suppliers into a warehouse) or outbound logistics (storing, transporting, and distributing goods to customers), logistics software can help your business improve production planning, sourcing, procurement, packaging, and dispatching.

Shipping Software

Shipping software integrates with eCommerce marketplaces and order management tools to help provide real-time shipping calculations for your products. These solutions prepare all the necessary documents from a single system and let you choose the carriers that provide the lowest cost and/or the best shipping services.

Advanced, cloud-based shipping software can be thought more like a freight broker/forwarding/management system, which is best for companies handling their own supply chain distribution process.

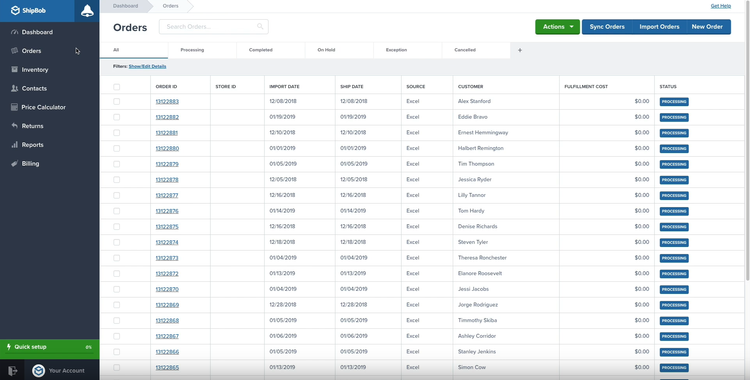

Order Fulfillment Software

Order fulfillment software automates order processing via sales order entry, inventory management, picking and packing items, and tracking shipments of goods to customers. These software options help simplify the workflows needed to efficiently ship the most goods in the shortest amount of time.

Order fulfillment is typically a feature set within a supply chain management software. These larger enterprise-level systems usually include additional capabilities like demand planning and sales forecasting.

Demand Planning Software

Demand planning software is a sales and operations planning (S&OP) technology that meets customer demand with the necessary level of supply. The software coordinates data from separate units of the business (primarily sales, marketing, and operations) to make more informed supply chain decisions.

Demand planning software is a forecasting solution that improves your supply chain performance. It’s similar to sales forecasting software, which better prepares your business and sales team with expected sales and revenue that you plan to achieve over a set length of time.

Procurement Software

Procurement software allows you to issue orders for services and products by tracking all key order info in real-time, including the vendor, purchase quantities, item or service purchased, delivery timeframes, payment terms, and costs. A cloud-based procurement system will handle submitting requisitions for approval, to sourcing, tracking purchase orders, and reconciling receipts and invoices.

Procuring needed goods and materials is a key cog in the supply chain wheel. For example:

- Receiving management functionality provides tools for verifying that goods have been properly resolved. It also puts in place workflows that allow for the timely resolution of instances where items are not received on time, in proper condition, or at all.

- Automatic or recurring purchase orders enable the creation of procurement orders in the future when particular conditions have been met and provide a means of significantly decreasing the labor associated with authorizing purchasing events

Warehouse Management (WMS) Software

Cloud-based warehouse management packages make it possible to manage and coordinate inventory and actions throughout a warehouse or distribution center. In order to oversee warehouse operations, WMS software gives warehouse managers powerful tools to:

- Design a warehouse’s workflow

- Control stock

- Generate bills and reports

- Manage yards, docks, and labor

WMS software leads to a higher accuracy of order fulfillment, optimizes picking and shipping, and leads to faster delivery times.

What Does Your Business Need?

The best management software for any supply chain partner depends entirely on the scope of your business. Selecting the right supply chain management system to meet your organization’s needs may depend on its size:

- Small business supply chain management software should integrate with existing small-business-friendly software solutions such as QuickBooks Online. Offering extensive inventory and order management capabilities while maintaining compatibility with existing systems makes for an easy transition and can help save costs compared to a full-scale SCM system.

- Mid-sized software should integrate with complex warehousing operations and may require integrations with larger enterprise resource planning (ERP) systems.

- Large businesses may require full-scale SCM packages providing a complete supply chain visibility solution from the ground up. Enhanced business intelligence and product forecasting tools can help large enterprises better predict and manage future resource demands.

Pain Points

- Choosing the right solution. Supply chain partners that manage delivery fleets have very different needs than organizations that outsource delivery solutions. It’s important to assess the specific needs of your supply chain operation to ensure you select the right software to meet your needs.

- Integrating with existing ERP systems. While most SCM solutions are designed with software integrations in mind, seamlessly integrating with ERP suites can be a time-consuming, resource-intensive process. Suppose the cloud-based software must be integrated with an existing solution. In that case, it’s crucial to evaluate both the supply chain management features your organization requires and the scope of the ERP integration it requires.

Market Trends

Here are some of the most common trends SCM software providers have developed solutions for:

- Cloud-based software: Most industries have begun migrating software operations to a cloud-based solution. Often paid on a recurring subscription basis, the cloud makes accessing information through any web browser easier, enabling better global supply chain management. Cloud-based software can also help save costs on computer hardware and server equipment.

- Internet of Things (IoT): The IoT increases transparency in the modern supply chain process. This includes GPS tracking and RFID technologies to monitor the transportation process, digital sensors on assembly lines to monitor quality control, or cloud-based solutions to streamline communication efficiency between different internal departments, third-party logistics providers, or other partners involved in the supply chain.

- Omnichannel retailing: The convergence of online and in-store purchasing has been made possible by decades of improved logistics capabilities. As such, any successful omnichannel retail operation needs precise control across supply chains, including warehouse management, inventory control, and transportation management.