The Best Import Export Software

Import-export software allows you to manage and track shipping, customs documentation, and compliance in international trade. We tested various systems for freight forwarders, manufacturers, and distributors and chose our favorites.

- Can integrate with CRMs, accounting systems, 3PL partners, and shipping carriers

- Easy upgrading with automatic access to lastest software features

- Multi-currency support

- Traceability (lot tracking)

- Customizable based on industry

- Advanced landed cost tracking

- Automatic container tracking and updates

- Customizable for all industries

We’ve evaluated a handful of options on the market and chose our favorites, including Magaya, Blue Link ERP, VISCO, and Acctivate.

- Magaya: Best for Freight Forwarders

- Blue Link ERP: Best for Importers and Exporters

- VISCO Software: Best for Global Trade

- Acctivate: Best for Wholesalers and Distributors

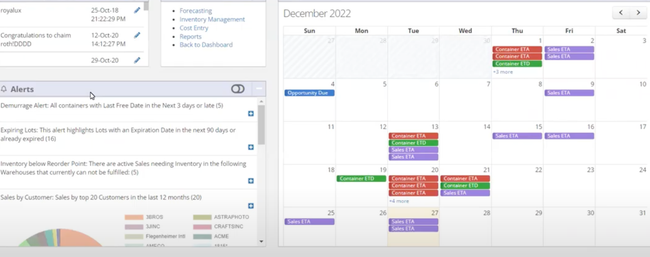

Magaya - Best for Freight Forwarders

Magaya’s automated documentation feature can help you quickly create and share shipping and logistics-related records. Suppose you’re a freight forwarder trying to send an electronics shipment from the U.S. to Germany. In that case, you can use Magaya’s feature to generate a commercial invoice, packing list, and bill of lading already pre-filled with the correct information.

Magaya will check German customs requirements to ensure the documents comply with EU regulations. It’ll then submit all necessary forms electronically to customs authorities in Germany for pre-clearance. Simultaneously, you can forward emails of the auto-generated documents to your shipping carrier and consignee.

This automation can help save you hours of manual work, reduce your risk of errors, and eliminate shipment delays. Magaya’s pricing starts at around $200/user/month, making it an affordable solution compared to other options like Blue Link ERP, which starts at $500/month.

Blue Link ERP - Best for Importers and Exporters

Blue Link ERP’s landed cost tracking feature allows you to gain accurate visibility into the actual cost of your products. This capability takes into account various cost factors, including:

Freight and shipping costs Insurance fees Customs duties and tariffs Brokerage fees Handling charges

Integrating these costs into your inventory value ensures that the COGS is accurately reflected in the system, which is essential for pricing, profitability analysis, and financial reporting.

When goods are purchased, you can input purchase order information and associated costs, such as shipping and customs fees. Blue Link will allocate these expenses to individual items using predefined allocation rules.

The database will automatically update the total landed cost of each product as additional fees incur. The inventory valuation will reflect these prices, ensuring accurate profitability tracking.

Blue Link ERP pricing typically ranges from $500 to $3,500 per month. However, the price can vary depending on the number of users and customizations required.

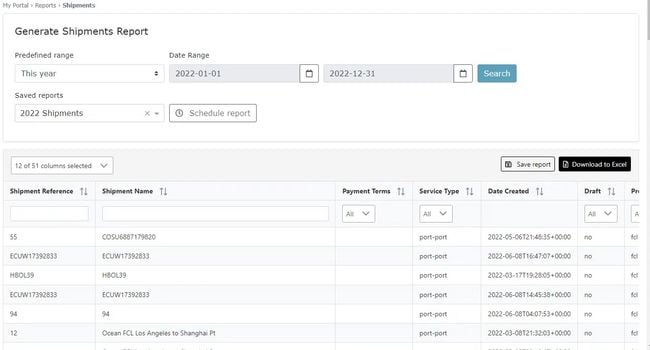

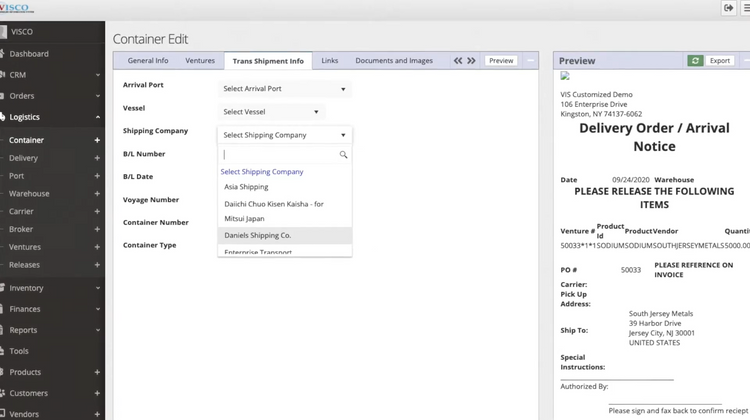

VISCO Software - Best for Global Trade

VISCO software is a global trade ERP system designed for importers and distributors. The software specializes in landed cost calculation, shipment and inventory tracking, and document generation and management. It offers a wide range of features to help you manage your business processes and improve your efficiency.

VISCO is designed around ventures, which are purchase order shipments. This lets you view shipments “in transit” and begin to gather costs and accruals against that venture. When inventory is sold, they post sales against the venture as well. This process is completely automated within VISCO.

Other features include:

- Inventory Management: With VISCO software, you can manage your inventory across multiple locations, track your inventory levels in real-time, and set reorder points to ensure you never run out of stock.

- Purchasing: VISCO offers comprehensive purchasing features, including purchase orders, vendor management, and invoice processing.

- Sales: You can manage your sales processes with VISCO software, including order management, invoicing, and customer management.

- Shipping: VISCO offers shipping features, including carrier integration, packing lists, and bill of lading generation.

- Regulatory Compliance: VISCO is designed to help you comply with regulations such as FDA, GHS, and CFIA.

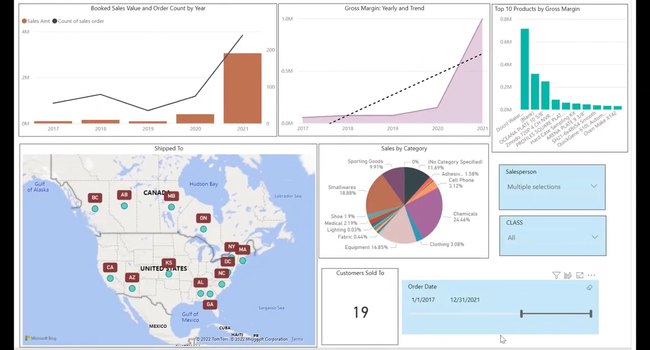

Acctivate - Best for Wholesalers and Distributors

Acctivate is a powerful inventory and order management software designed for wholesalers and distributors. It offers a wide range of features to help capture costs, manage inventory, handle customers, and create price structures — all while being efficient and profitable.

Acctivate also offers landed cost tracking to accurately calculate the true cost and profitability of goods. This includes additional costs such as duties, taxes, VAT, government fees, freight, and insurance in product valuation.

Acctivate is suitable for small and mid-sized importers as it offers affordable management of global trade and regulatory compliance. It supports multi-currency accounting, allowing you to set prices in specific countries where you want to do business and easily handle currency conversions based on the current exchange rate.

Other features include:

- Inventory Management: With Acctivate, you can manage your inventory across multiple locations, track your inventory levels in real-time, and set reorder points to ensure you never run out of stock.

- Order Management: Acctivate offers comprehensive order management features, including sales orders, purchase orders, and order fulfillment.

- eCommerce: Acctivate integrates seamlessly with eCommerce platforms like Shopify, WooCommerce, and Magento, allowing you to manage your online sales and inventory in one place.

- Shipping: Acctivate offers shipping features, including carrier integration, packing lists, and bill of lading generation.

- Regulatory Compliance: Acctivate is designed to help you comply with regulations such as FDA, GHS, and CFIA.

What Is Import Export Software?

Import export software provides landed cost tracking, multi-currency support, and warehouse management capabilities to aid inventory logistics. Used by distribution and wholesale companies, import export software can be thought of as a subset of distribution software–helping improve global trade operations through fully integrated processes that improve traceability in your logistics business.

The best import export software will usually come in the form of a fully-integrated ERP software that includes the previously mentioned functionality, as well as processes for accounting, order entry and invoicing, customer relationship management (CRM), shipping, and automated customs processing. The right solution will manage global trade and comply with all regulatory requirements, allowing your business to buy and sell globally easily and efficiently.

Routine tasks that surround the import and export process, such as re-keying important documents and being compliant with your electronic data interchange (EDI) are included with import export software. This allows you to implement a multi-national pricing strategy to calculate the true cost and profitability of goods with landed cost.

Key Features

- Landed Cost Tracking: Accounts for all costs associated with getting inventory into your warehouse. Commonly tracked costs include duty, brokerage, freight, insurance, storage, wharfage, and more. Through tracking shipments of imported goods and monitoring the estimated arrival times of shipments, determine an estimate of the overall cost.

- Accounting: Tracks financial transactions to record profit loss and better improve business finances and overall cash flow. Includes a general ledger, accounts payable (AP), and accounts receivable (AR). Can also includes multi-currency accounting, which helps record profits and liabilities in any base currency after being converted from any number of transaction currencies.

- Inventory Management: Tracks all information about the items that your company builds, buys, stores or sells. Inventory management systems simplify pricing products and helps maintain the most effective stock levels.

- Order Management: Streamlines order processing by helping merchants capture, track, and fulfill orders across multiple sales channels (multi-channel order). Connects inventory and sales orders, creates shipping schedules, tracks fulfillment, and creates reports.

- Purchase Orders: Creates the financial documents issued to vendors when you are buying supplies or services. Includes information such as product type, quantity, and pricing.

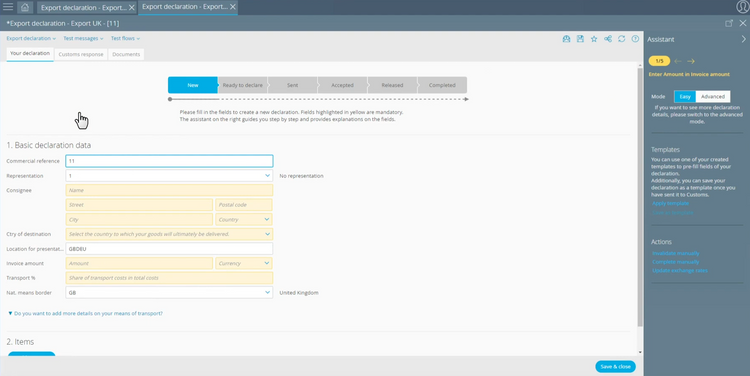

- Automated Customs Processes: Simplifies international trade procedures by automating customs documents through computer-assisted transmission. Ensures compliance with government rules and regulations, helps collect duties and taxes due according to the national Customs tariff and tax code, and protects against the import of illegal goods.

- Warehouse Management Tools: Manages and coordinates inventory and actions throughout a warehouse or distribution center. Gives warehouse managers powerful tools to design a warehouse’s workflow, control stock, schedule labor, generate bills, analyze reports, and coordinate with shipping yards and docks.

Primary Benefits

Import/export systems can determine the cost and profitability of the products your business deals with–helping you maintain a consistent pricing strategy and allowing for more visibility into your inventory.

Track Landed Cost of Imported Goods

Landed cost tracking provides visibility of imported goods through shipment tracking. It helps you track all associated costs involved in shipping the imported goods to your final destination.

There are often hidden costs involved in making certain goods available for sale. Your true cost will always be higher than the cost you pay to the vendor for the product. In addition to the price of the goods, you’ll have to handle freight, customs and duty costs.

Landed costs are important to track because they’ll help you calculate your profit margins on international transactions.

Eliminating these hidden costs from the final product price can also help you attract customers. Paypal states that https://www.paypal.com/us/webapps/mpp/passport

Ease Vendor and Customer Payments with Multi-Currency Support

Multi-currency support is an accounting method that allows for the input of two or more currencies. An example would be handling your accounting in both USD (U.S. dollars) and CNY (Chinese Yuan). Not only does multi-currency support make your accounting easier, but it also allows your international customers to pay in their preferred currency.

Having importing software with multi-currency support is vital. It’s much more than just simply calculating conversion rates. The cost of doing business in a specific country will vary depending on the product you’re importing and the time of year.

Multi-currency support will handle these conversions for you and l help you create a better business plan based on the information it provides.import export software

Foreign currency conversion applications allow you to keep your ledgers in the relevant local currency or even access the same financial information in the currency of your choice.

Additionally, with the right package, you can generate purchase orders and invoices in the right currency for your vendors and customers and maintain a price list for each currency.

Benefits of Multi-Currency Support

- Ensure customer loyalty by improving customer experience

- Avoid extra charges related to currency conversion rates

- Maintain consistent pricing across all locations

Calculate Import Duties

An import duty is a tax collected on imports and some exports by a country’s customs authorities. This tax is based on the imported good’s value. Depending on the context, import duties may also be referred to as customs duties, tariffs, import taxes or import tariffs.

A prime benefit of landed cost tracking is identifying the cost elements of imported goods–meaning import/export software needs to help importers calculate import duties on their products.

Due to rising import tariffs, some manufacturers have pulled certain models of their products from specific markets. As tariffs rise, more and more products will be affected. For example, companies can see a 10 percent tariff on Chinese imports–meaning importers need a way to plan accordingly.

Import duties, freight and insurance are all direct costs that we need to factor into the landed cost equation. Luckily, a smart enough import/export software will include this as a feature of its landing cost accounting functionality.

To find the accurate gross margin, you need to attribute both freight costs and duty costs between products. Once determined, you’ll have your total landed cost.

Control Inventory with Warehouse Management

Warehouse management is the process of managing inventory on an increased scale across multiple locations. At its core, import/export software helps you pick, pack, and ship orders. Complete warehouse management software functionality will include capabilities such as inventory control, order fulfillment, and purchasing.

Warehouse management software can typically integrate with your business’s existing order and operating processes. A warehouse management module helps you see where an order is in the shipping process, gives crucial insight into how fast orders are completed, and helps identify potential weak points in your warehouse processes.

Technology also continues to improve in warehousing, as barcoding and RFID technology allow importers to view inventory in real-time. The best warehouse management software providers are already implementing such emerging technology into their solutions.

Benefits of Warehouse Management Software

- Increase the accuracy of order fulfillment

- Shorten delivery times

- Reduce overflow of on-hand inventory

- Increase the visibility of an order’s status

- Optimize storage space

- Minimize inventory movement