The Best Manufacturing Quoting and Estimating Software

Manufacturing quoting and estimating systems help generate accurate cost estimates and quotes for manufacturing processes. We evaluated the top systems on the market and reviewed them below.

- Simple and straightforward software

- Easily configurable for manufacturing processes

- Reasonable pricing

- Affordable, transparent pricing

- Real-time inventory tracking across locations

- Data-driven decision-making support

- Focus on manufacturing processes

- Handheld scanners and RF-enabled PDAs

- Reduced computer need on plant floor

Manufacturing quoting and estimating software helps determine the cost of a project’s materials, labor, and more. Using our software review process, we’ve determined these are some of the top products:

- Costimator: Best Overall

- Katana MRP: Best MRP

- DELMIAWorks: Best for Job Costing

- SecturaFAB: Best for Metal Fabricators

- Paperless Parts: Best for Custom Parts Manufacturing

- MRPEasy: Best for Small Businesses

- JobBOSS²: Best for Job Shops

- DigiFabster: Best for Additive Manufacturing

- Global Job Shop Solutions: Best ERP

- Acumatica: Best for Manufacturers’ Representative Firms

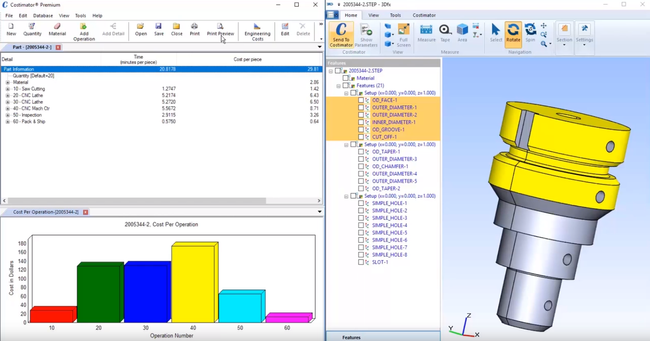

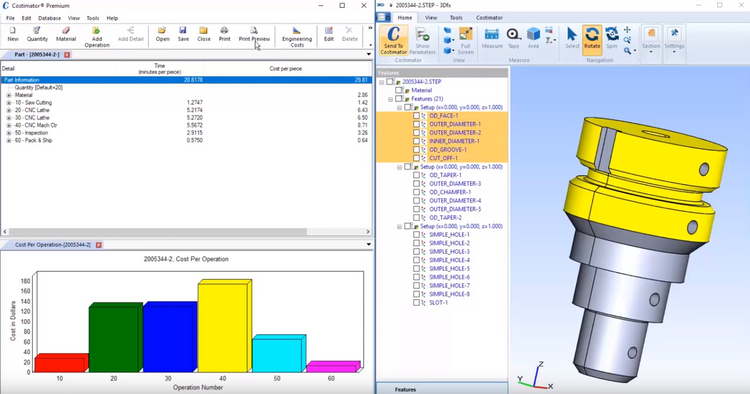

Costimator - Best Overall

Costimator is a top quoting and estimation solution due to its user-friendly interface and efficient quote generation process, which involves five straightforward steps. With the ability to calculate cycle times and manufacturing costs based on your equipment and shop rates, Costimator JS ensures that your quotes are precise and competitive.

Costimator works for a variety of different manufacturing types, including:

- CNC machining

- Welding

- Sheet metal

- Assembly

With features for generating formal quotes and management reports, Costimator offers an effective solution for manufacturers looking to enhance their quoting and estimating processes.

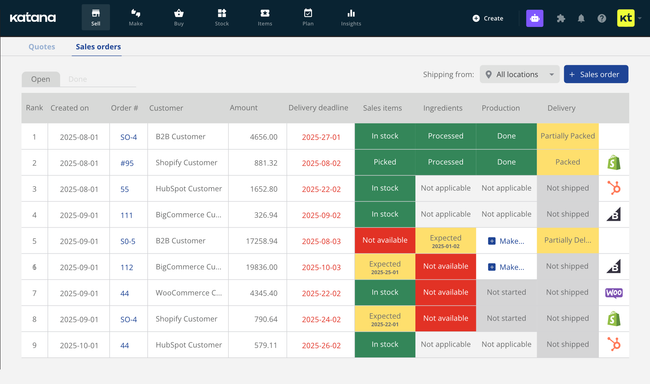

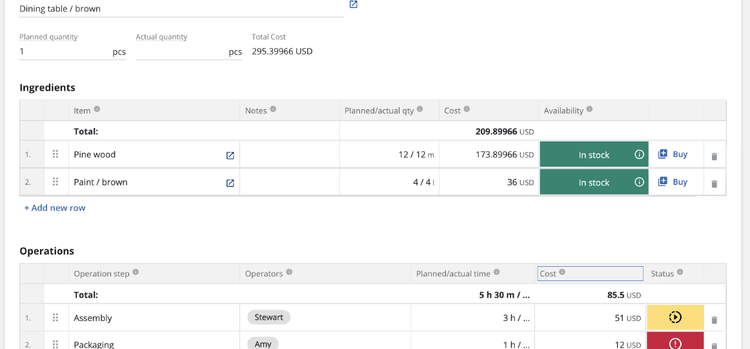

Katana MRP - Best MRP

Katana MRP uses real-time inventory management to give businesses better control over materials and products. The module lets you see on-hand, committed, and expected stock for each item, so you always know exactly how much inventory you have for popular products. The system displays the data on a color-coded, modern interface that helps you see information at a glance.

Additionally, Katana’s product and material inventory has live counts to ensure accurate quotes and estimates before sending them to the customer. Once the client accepts the estimate, you can convert it to a sales order, and the system automatically allocates inventory. This helps guarantee you reserve the necessary raw materials for production, leading to better planning as new orders arrive.

Katana MRP offers competitively priced packages for small to midsize manufacturers. All packages come with unlimited users, SKUs, and integrations, which is a plus if you have a higher user count compared to per-user pricing models. Unfortunately, features like traceability, forecasting, and warehouse management are only available in the highest-priced Professional package at $799/month billed annually, which can be too steep for smaller operations.

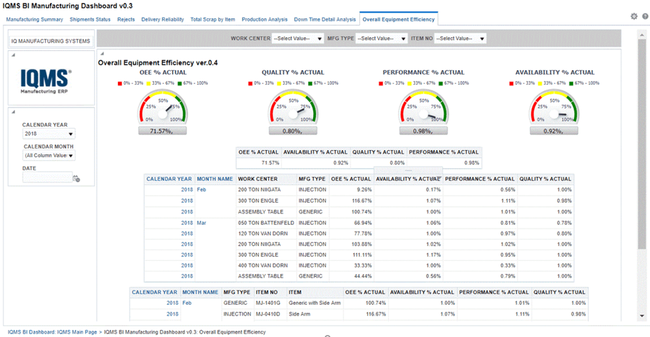

DELMIAWorks - Best for Job Costing

DELMIAWorks, previously known as IQMS EnterpriseIQ, is a strong choice for businesses needing manufacturing quoting and estimating software due to its comprehensive and integrated approach. The add-on module, JobShopIQ, efficiently manages job shop operations within the same system used for other manufacturing processes. This level of integration provides businesses with the agility to respond quickly to changing demand, resulting in increased efficiency and reduced operating costs.

The advanced features, such as optimized and global visual scheduling, ensure that resources are allocated efficiently and that production schedules are consistently met. The ability to quote new projects quickly and accurately positions DELMIAWorks as an excellent choice for manufacturers seeking a solution for quoting and estimating.

SecturaFAB - Best for Metal Fabricators

SecturaFAB is ideal for metal fabricators, offering a strong estimating module with geometry, conversion, and CAD editor tools for customer file clean-up. This is paired with its true-shape nesting algorithms to optimize the amount of materials needed and support several different CAD file types, such as SolidWorks files, vector PDF, and DXF. Its bend recognition and fillet weld detector further specify costs for steel fabricators by applying calculators for accurate estimates.

It also has a built-in CRM and price management modules for optimizing sales processes. Companies can manage vendors and quotes and integrate an ERP to easily view existing quotes and sync data across multiple systems. Users can apply costing rules for weight, time, volume, and distance metrics. However, these specifications can take some time to set up and configure according to specific business requirements and products.

Paperless Parts - Best for Custom Parts Manufacturing

Paperless Parts is designed for manufacturers that quote highly variable, custom-engineered parts. Its geometry quoting engine analyzes 3D models and 2D drawings to detect features, flag potential issues, and build standardized cost structures for estimators. This reduces the guesswork for job shops and helps teams price complex parts with confidence, especially when quoting CNC or sheet metal work.

Another feature that custom parts manufacturers will appreciate is the digital quoting experience. It replaces the manual processes of sending PDFs back and forth with an online portal. Customers can view pricing options, compare quantities, and approve quotes directly from a custom-branded interface. This helps job shops present themselves professionally and provide quicker quotes, which is invaluable for small teams looking to win more bids. It’s also ITAR-compliant, so DoD manufacturers don’t have to worry about sending sensitive drawings through unsecured channels.

And once the RFQ is received from the online portal, Paperless Parts Wingman AI extracts materials, tolerances, certifications, and special requirements directly from the customer’s documents and drawings. This reduces the time spent searching through emails, ensuring you don’t miss anything before you start production.

Pricing is quote-based and is typically best for growing or established job shops. Smaller one or two-man operations may find its features expensive compared to other low-cost estimating platforms. That said, Paperless Parts integrates with most leading manufacturing ERPs like Epicor, ECI JobBOSS², Infor, and Global Shop Solutions, allowing you to keep your existing software.

MRPEasy - Best for Small Businesses

MRPeasy is an MRP best suited for small manufacturers in a variety of industries. The software’s cloud-based nature makes it accessible and easy to implement. MRPeasy offers strong features on a user-friendly interface, including tools for production planning and scheduling, CRM with manufacturing cost estimating, and more.

The competitive pricing, starting at $49/user/month with a free trial option, makes it an attractive option for small to medium-sized manufacturing teams with 10 to 200 employees.

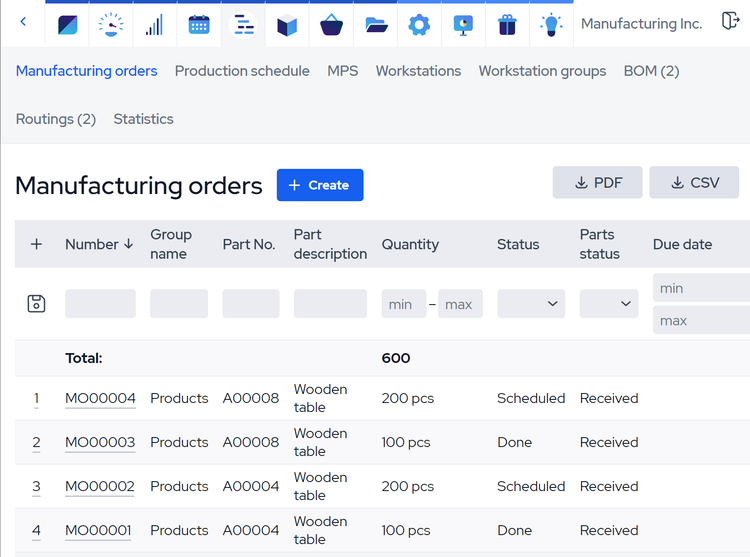

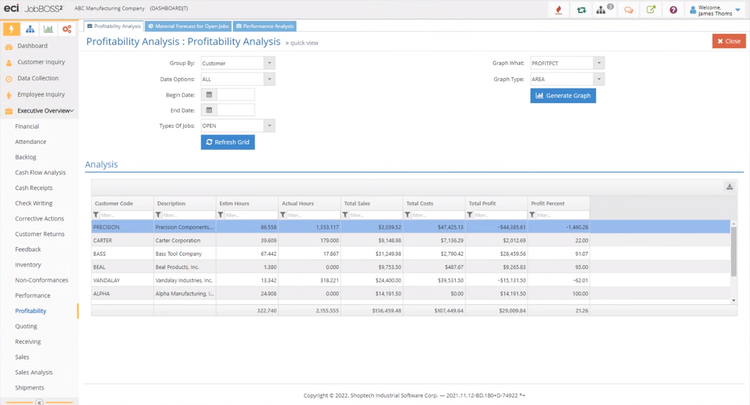

JobBOSS² - Best for Job Shops

JobBOSS² is a practical solution for small to medium-sized manufacturers. This software is ideal for companies with 10-100 employees who are transitioning from manual methods as they grow. Its estimating and quoting module allows for pre-set configurations for several rates, including burden and labor rates, run/cycle time, and sales commissions. This helps companies understand profit margins and stay on budget.

However, it’s worth noting that JobBOSS² may not be the best choice for process manufacturers due to the absence of industry-specific functionalities needed for formula-based production and variable product yields. Despite this, JobBOSS² is still a top option for job shops looking to move away from spreadsheet-based quoting and estimating.

DigiFabster - Best for Additive Manufacturing

DigiFabster stands out for its adaptability and efficiency for additive manufacturers. It supports a range of technologies suitable for various shop sizes, making it a versatile option for businesses using 3D printers and CAD files. The software offers strong features, such as instant CAD analysis for quick and accurate quoting, the ability to fix potential geometry issues, and intelligent, geometry-based pricing that leverages machine learning. This results in quotes with a high degree of accuracy.

DigiFabster also offers CRM and order management capabilities to streamline the quoting-to-fulfillment experience. The platform’s flexibility is evident in its customizable features, such as pricing triggers, discounts, and integration with accounting software like QuickBooks or Xero. These features, coupled with its ability to handle multiple languages and units of measurement, make it ideal for additive manufacturing.

Global Job Shop Solutions - Best ERP

Global Job Shop Solutions is an ERP system offering a range of features such as SPC, CRM, inventory control, and scheduling. Tailored for small to mid-sized manufacturers in the automotive and aerospace industries, it offers support for mixed-mode manufacturing, payroll, and time tracking, and its capability to streamline HR processes is a notable strength.

During our review, we found this platform particularly benefits businesses that value thorough production support and responsive customer service. Still, it may require a considerable investment in employee training and adaptation.

Acumatica - Best for Manufacturers’ Representative Firms

Though Acumatica provides full ERP functionality, the estimates module within its quote-to-cash workflow is particularly strong for manufacturers’ reps. The process begins in the CRM workspace where your reps can log opportunities, like a buyer request for custom or high-volume pricing. From there, the rep can launch a quote directly, preserving the entire sales context.

In the estimates module, your reps can build detailed pricing proposals using a copied bill of materials or a flat pricing structure. They can tweak material and labor costs, apply markups, and send buyers branded, itemized quotes. Acumatica includes a DocuSign integration for electronic quote approval, which is auto-logged to the customer record.

After approval, Acumatica converts the quote into a sales order. You can configure these to trigger drop-shipments, notify manufacturers, or integrate with a fulfillment partner. Acumatica starts at around $1,800/month; small businesses can expect to pay around $21,000 to $34,000/year. If you’re a smaller rep firm focused on quoting and commissions, a tool like TurboPro might be a better fit.

What is Manufacturing Quoting and Estimating Software?

Manufacturing quoting and estimating software helps generate quotes based on the costs for materials, labor, overhead, and more. Also known as shop floor cost estimating software, these solutions aim to maximize time and profits with accurate and straightforward pricing details. These quotes analyze past estimates and look at which ones turned into sales and which ones did not–helping manufacturers close more sales by customizing efficiency rates, scrap percentages, and other variables.

An industry-specific type of configure, price, and quote systems (CPQ software), manufacturing quoting and estimating software helps your business get from quote to cash. Providing customers with an accurate quote is one of the biggest factors in whether a company decides to do business with you–and delays in putting together a quote can stop a deal from occurring altogether. This software will provide insight into the real-time prices and materials, labor costs, and current capacity.

Storing information on past quotes and estimates helps put together accurate quotes quickly and easily. This also lets you check the inventory of parts, materials, and purchases during your quoting process, and allows you to ultimately gain insights into your profit margins through parts costing.

Key Features

- Quoting and Estimating: Import part structure and work orders to generate estimates. Grab data from online order entry programs including any modifications, important tracking details, or special needs inquiries. Calculate the costs of any bill of materials structures. Allow for multiple proposals per bid. Create “what if” scenarios to modify mark up rates on the fly.

- Document Management: Associate documents with an estimate and store copies within the software. Allow export of the files to Excel.

- Labor cost, material, and equipment cost tracking: Quantification for employee hours and job-specific rate management. Calculation of material costs based on defined material base rate costs and input of quantity requirements. Calculation of costs likely to be incurred for payment of subcontractors in the performance of job responsibilities. Cost calculation capabilities for the purchase or rental of equipment required to complete job work.

- Cost Analysis: Determine the sum of costs of all resources consumed in the process of making a product. Break down costs based on materials, labor, and overhead. Run reports on production costs vs manufacturing costs. Account for split order commission rates among salesmen.

- Price Optimization: Determine how demand differs at varying price points and weigh that data against inventory levels to find the most profitable price point. Help determine standard pricing, promotional rates, discounts, and more.

Primary Benefits

The top benefits of using estimating and quoting software for manufacturers include:

Standardize Pricing

Creating quotes and estimates via manual methods includes a large time investment in grabbing pricing from large databases or spreadsheets. This time-consuming process means your estimates end up in your customer’s hands later than your competition, putting you at a disadvantage.

Fortunately, complicated pricing structures can be built into manufacturing software to provide price standardization. Manufacturing quoting software lets you use existing master inventory items and price breaks to create quotes on the fly, helping you keep up with competitors.

Streamline The Sales Process

Manufacturing estimating software speeds up when orders can be finalized and moved into production due to less time spent digging for the necessary information during the quote creation process. Because of this, customers receive a more engaging experience. Rather than sit around waiting for a quote, customers can commit to their order right away when you use software to create accurate estimates.

By eliminating the concern of how long it may be before a manufacturing estimate can be created, customers can now freely request orders without delays. Manufacturing businesses can focus on improving their response time during production rather than having potential orders tied up by an inefficient sales process.

Stay Within Your Margins

With the level of complex products being made by manufacturers today, there is a need to produce highly-specific configurations that require participation from both business and engineering teams. Manufacturers continue to have their margins tested and squeezed further than before. This is due to non-standardized quotes, discounting, and rebates that may be a factor in issuing a price quote to a customer.

Implementing a manufacturing quoting and estimating system helps eliminate the chance of these non-standardized quotes. This insight shows you know which departments or channel partners produce products most consistently within your preferred margins. This creates more uniformity and consistency for any individuals (such as resellers) and ensures your product is sold at a more true rate.

Increase Automation Functionality in eCommerce Manufacturing Processes

eCommerce software capabilities let manufacturers sell their goods and services online, including the ability to automatically update inventory, calculate taxes, and anything else necessary to fulfill orders. This includes providing accurate price estimates to ensure the profitability of your business.

One of the most important reasons to integrate your manufacturing quoting and estimating software within your eCommerce operations is for a detailed, price-itemized bill of materials (BOM) displays. This provides a visual configuration and representation of what your customer is looking to accomplish.

Integrated quoting and estimating within eCommerce platforms helps eliminate the more cumbersome request-for-quote (RFQ) process. You may even give the customer the ability to generate the quote on their own–meaning they can immediately lay the foundation for the product they want with immediate pricing. This means your customers are actively working for you in building their quotes, and you’re also making them feel more included in the price quote process.

Pricing

Quoting software for manufacturing ranges from $1,200 to over $250,000/year, though costs vary based on user count, the number of modules included, and any desired integrations. Below is a table summarizing the total cost of ownership for manufacturing quoting and estimating software.

| Tier | Size | TCO | Example Software |

|---|---|---|---|

| Low-Tier | 1–25 employees or <$2M annual revenue | $1,200–$6,000/year | Costimator, MRPeasy, Katana |

| Mid-Tier | 25–150 employees or $2M–$20M revenue | $6,000–$30,000/year | JobBOSS², SecturaSOFT |

| High-Tier | 150–500 employees or $20M–$100M revenue | $30,000–$100,000/year | Fulcrum, EstiTrack |

| Enterprise | 500+ employees or $100M+ revenue | $100,000–$250,000+/year | DELMIAWorks, Aptean Industrial ERP, Infor CloudSuite Industrial |

High-tier and Enterprise Packages are often complete ERP or MRP platforms that provide more than just manufacturing quoting and estimating capabilities. They frequently include tools for job costing, inventory management, and shop floor control, in addition to manufacturing quoting.