Best Inventory Management Software

We tested and reviewed the top inventory management software on the market and selected our favorites for retailers, 3PL providers, and manufacturers.

- Integrates with QuickBooks Online, ShipStation, and Shopify

- Affordable pricing for SMBs

- Mobile app for warehouse inventory management

- Competitive pricing; does not require a subscription

- Integrates with QuickBooks

- Can function as a light MRP system

- Provides batch tools through the order manager to track process workflows

- Integrates directly with QuickBooks for easy data migration

- Can handle millions of SKUs for scalability

Inventory management software extends beyond tracking your warehouse or retail store stock. The best inventory systems recognize combinable parts, sync with supply chain partners for consistent stock availability, and update customers with shipping estimates.

Here’s a rundown of our top picks based on user reviews and our internal review process.

- SOS Inventory: Best Overall

- Zoho Inventory: Best for eCommerce Retailers

- Acctivate: Best for QuickBooks Users

- Fishbowl: Best for Manufacturers

- Cin7 Core: Best for Wholesalers

- Extensiv: Best for 3PL Providers

- Katana: Best Production Tools

- ShipBob: Best for Direct-to-Consumer

- inFlow Inventory: Most Intuitive Design

- Sortly: Most Affordable Option

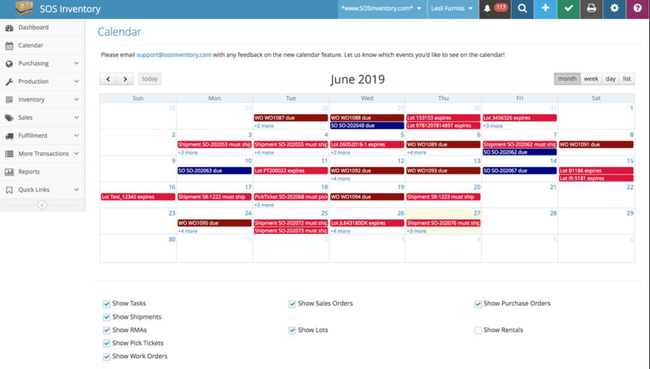

SOS Inventory - Best Overall

SOS Inventory makes it easy to track high-value, regulated, or perishable goods with built-in traceability tools. It’s a solid pick for smaller companies in industries like food processing or manufacturing, where strict inventory control and accurate record-keeping are vital.

From the moment you add an item to the system, you can enable lot and serial tracking. Lot codes tie stock to specific production batches, making it easier to follow regulations like FDA, USDA, and ISO standards. Serial numbers assign unique identifiers to each product so warranties and service records stay accurate. Every time stock moves—whether it’s a purchase, transfer, or sale—SOS Inventory records the exact lot or serial number, giving you a clear history of every item.

Advanced item data fields let you add more than just a name, price, and description to your products. You can assign barcodes and SKUs to cut down on picking and shipping errors. Plus, you can link items to specific vendors and their part numbers to make ordering easier. If you need something more tailored, you can even add custom fields to track the most important details for your company.

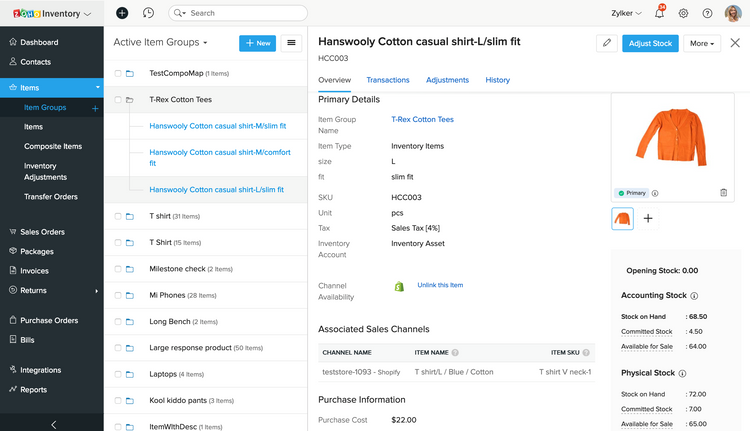

Zoho Inventory - Best for eCommerce Retailers

Zoho Inventory provides a free inventory management system designed for growing businesses. It handles stock management and multi-channel order fulfillment, suitable for retailers with various products and sales channels like Amazon, eBay, and Shopify.

Ideal for micro online sellers, drop-shippers, retailers, and distributors, Zoho Inventory starts at $39/month per organization billed monthly. The solution is cloud-based, meaning you can access it by virtually any mobile device with an internet connection. Overall, Zoho Inventory enables retailers to capture leads and prospects, create orders, and manage online marketplaces’ sales channels and inventory levels.

However, if you want to review purchase orders and invoices fully, you’ll need to integrate with Zoho Books for this functionality. Additionally, you’ll need Zoho Commerce for a shopping cart tool and Zoho CRM for comprehensive customer management.

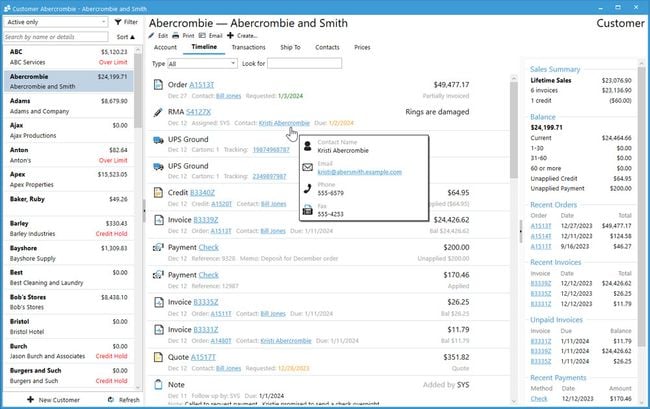

Acctivate - Best for QuickBooks Users

Acctivate’s integration engine is built specifically for syncing with both QuickBooks Desktop and QuickBooks Online. It’s a go-to pick for businesses that have outgrown QuickBooks’ native inventory tracking but want to stick with its accounting functionality.

When first connected to QuickBooks:

- Acctivate pulls in your core QuickBooks lists, like items, customers, and currencies

- Inventory quantities in QuickBooks are zeroed out and deactivated to avoid double-booking

- Acctivate takes over all inventory-related transactions

This integration is fully bi-directional; invoices created in the system automatically carry all item-level details into QuickBooks, and customer record changes are reflected across both platforms. We also liked that you can run syncs manually or set them on a schedule, making it adaptable to various workflows.

Acctivate starts at $5,000 for an annual subscription or $5,995 for a one-time initial license fee. This includes support for one user, inventory management, and warehouse automation. However, Acctivate doesn’t support RFID scanning.

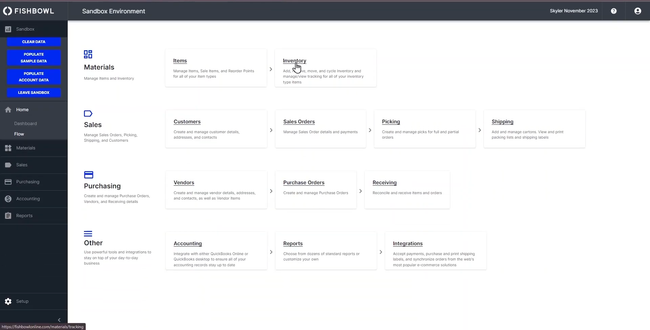

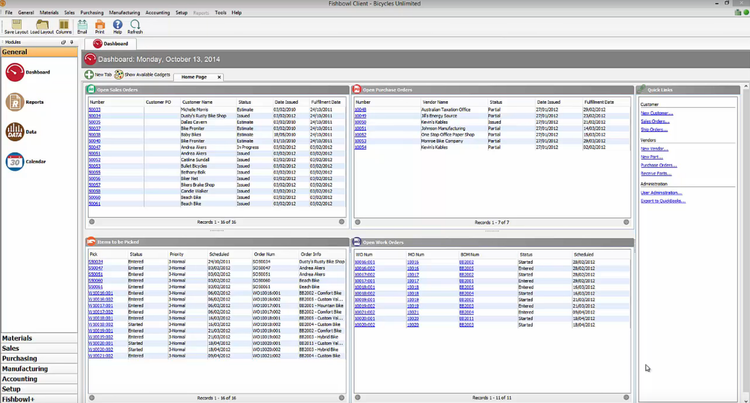

Fishbowl - Best for Manufacturers

Fishbowl Inventory’s MRP tool records past usage data and vendor lead times, helping you set smart reorder points. It constantly monitors stock levels as you use and replenish materials, so you’re always prepared. You can set safety stock levels to handle sudden delays or demand spikes. Plus, the bill of materials module lets you create bills of materials (BOMs) that fit your specific manufacturing processes.

Fishbowl integrates with QuickBooks Online and QuickBooks Desktop. The platform was designed to “fill in the gaps” regarding QuickBooks inventory capabilities like barcode scanning. It was one of the first third parties to receive Gold Developer status from Intuit. This status with Intuit gave them key information to remain compatible with all new versions of QuickBooks that continued to roll out over the years.

Additionally, Fishbowl integrates with EDI software, shipping carriers, and eCommerce solutions like Shopify, Amazon, and Woocommerce. On the other hand, the Windows-based navigation panes can make the UI feel slightly dated. And you’ll have to manually sync Fishbowl with QuickBooks, so transactions do not post in real time.

Cin7 Core - Best for Wholesalers

Cin7 Core offers an effective B2B sales portal for wholesale sellers. Using this tool, your customers can easily access your product catalog, place orders, and set delivery timelines from one central location. This can save you a ton of time on phone calls and emails with businesses haggling over prices and discounts. Now, you can update your prices in real time, so companies can place orders on their own and save you time on manual data entry.

The B2B portal also helps manage payments. Customers can view their order history, invoices, and deliveries from one place. Plus, the checkout has a wholesale payment gateway that makes the process seamless. The system instantly updates stock counts after each order, ensuring quick resupply after bulk sales.

Additionally, the portal integrates with QuickBooks Online and Xero, so you don’t have to worry about siloed data. All sales, invoicing, and payments automatically sync and reconcile with your books. This way, you can be sure the data is accurate and you don’t need to transfer it from the portal to your accounting system manually.

Cin7Core is pretty affordable for small to midsize wholesalers that may have outgrown a smaller system like QuickBooks Online. For growing businesses, the Pro plan starts at $599/month for 10 users and 24,000 sales orders/year. However, the initial setup can be a little complex; fortunately, Cin7 offers onboarding packages, though they come at an added cost.

Extensiv - Best for 3PL Providers

Extensiv 3PL Warehouse Manager’s rule-based order routing streamlines fulfillment across multiple warehouses, clients, and shipping carriers. The system automatically directs incoming orders through optimized workflows, whether they’re coming from eCommerce platforms, EDI transactions, or marketplaces like Amazon.

You can configure rules based on:

- Stock Availability: Direct the order to a warehouse with sufficient stock to avoid backorders.

- Warehouse Proximity: Assign orders to the closest fulfillment center.

- Client Requests: Customize routing based on agreed service level agreements with 3PL clients.

- Carrier and Service Level Selection: Assign carriers based on the fastest delivery, lowest cost, or client preferences.

Once 3PL Warehouse Manager routes an order, it automatically assigns it to the correct facility and fulfillment workflow. It even generates picking lists and shipping labels based on the designated routing path. This can help speed up fulfillment, allowing you to grow and handle more clients without adding excessive labor.

Katana - Best Production Tools

Katana Manufacturing ERP features a visual production planning dashboard, simplifying supplier price monitoring and optimizing manufacturing processes to meet job orders. The smart auto-booking engine automatically assigns available materials to orders. Additionally, the system integrates with popular eCommerce platforms such as Shopify and WooCommerce, and accounting applications like Xero and QuickBooks Online.

Katana is a solid inventory management solution for small to mid-sized apparel, electronics, food, and aerospace manufacturers. It provides real-time updates on inventory levels, including on-hand, committed, and expected stock. Plus, Katana delivers manufacturing-specific capabilities like shop floor control and master planning.

However, Katana lacks a dedicated mobile app. It’s accessible via web browser on the shop floor, which may be a limitation for workers who prefer using an app-based interface.

ShipBob - Best for Direct-to-Consumer

ShipBob is ideal for DTC eCommerce businesses, particularly those experiencing rapid growth. One of its key advantages is a strong fulfillment network that offers 2-day shipping to most of the US population. With seamless integrations to online stores, ShipBob automatically processes orders, which are picked, packed, and shipped from strategically located fulfillment centers nationwide.

ShipBob gives full visibility into your inventory, including levels, movement, and historical data across all fulfillment centers. This lets you monitor your stock in real time and quickly resolve discrepancies. The dashboard delivers detailed insights into SKU velocity, the number of days remaining inventory will last, and demand forecasting. Additionally, ShipBob allows you to set reorder points and store inventory in multiple fulfillment centers strategically located closer to your customers.

Online user reviews highlight ShipBob’s exceptional service for direct-to-consumer operations. However, some feedback points to areas for improvement in their business-to-business (B2B) services. It’s designed for managing clients with low SKU counts and companies that don’t handle B2B orders from their own warehouses.

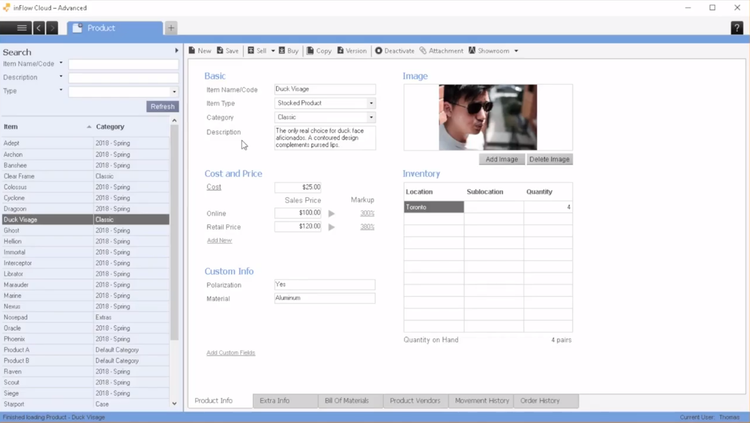

inFlow Inventory - Most Intuitive Design

inFlow Inventory provides a full-fledged feature set and ease of use for both small entrepreneurs and full enterprises. Overall, the software makes navigating various tasks and modules simple with a highly visual layout.

inFlow Inventory has customizable fields, allowing businesses to tailor their inventory system precisely to their needs. Additionally, the inclusion of a mobile app compatible with iOS and Android extends its functionality, enabling on-the-go tracking and operations. We also found the system quite scalable for growing businesses, handling up to 10,000 monthly sales orders.

However, we wouldn’t recommend inFlow Inventory for those seeking an on-premise solution. Support for inFlow On-Premise ended on July 31, 2024; new licenses are no longer sold or activated. Users will need to switch to the cloud version for updates.

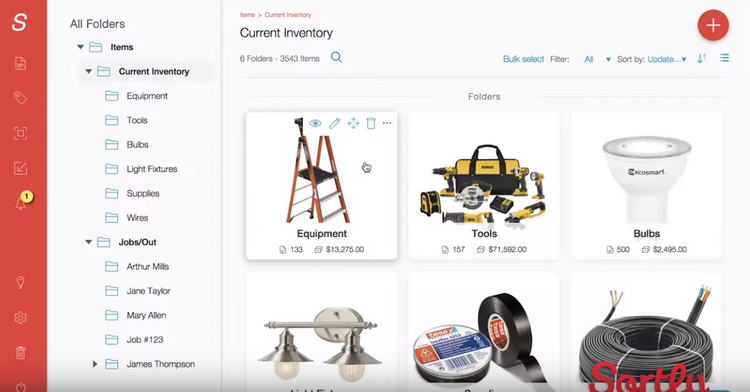

Sortly - Most Affordable Option

Sortly is intuitive and simple to use. It offers a free plan that supports up to 100 item entries and one user license. Paid plans start at $29/month for 2,000 item entries and two user licenses. Targeted at individuals and small businesses, Sortly offers a cost-effective approach to inventory management without compromising on essential features.

The software enables users to track items using pictures, tags, and customizable fields, making it user-friendly. Sortly’s mobile app supports barcode and QR code scanning, facilitating easy item check-ins and check-outs. Additionally, Sortly offers a unique feature that allows for creating visual inventory lists.

However, the number of custom fields you can add varies by subscription plan. The Ultra plan allows for up to 25 custom fields. The Enterprise plan has unlimited custom fields but requires a consultation call for pricing.

What is Inventory Management Software?

Inventory management software (inventory control software) keeps track of all information about the items your company builds, buys, stores, or sells. These systems simplify product pricing and help maintain the most effective stock levels.

Considered to be the key part of a distribution software, inventory management software lets you know exactly what you have on hand and where to find it. A smart inventory control module will also alert you when it’s most advantageous to re-order stock.

Critical business benefits enabled by inventory management systems include:

- Reduced stock level requirements and lower warehousing costs based on a better understanding of stock movement and inventory items

- Decreased expenses related to tasks such as picking, packing, kitting, and shipping of inventory based on more intelligent inventory movement management

- Higher customer satisfaction via visibility to on-hand stock levels and improved ability to set delivery expectations

- Minimization of theft and loss based on improved visibility of stock counts and movement histories that make forensic inventory loss analysis easier to conduct

Inventory Management Software Key Features

The features of inventory management software can be broken down into basic features, traceability features, and advanced features.

Basic Features

- Inventory costing: Provides the means of establishing the cost value of inventory for profitability tracking and tax accounting (cost methods include: FIFO, LIFO, average costing, and others).

- Location tracking: Aids in picking/packing/shipping tasks related to inventory items and helps improve inventory loss prevention

- Stock count tracking: Provides a record of the on-hand units for each SKU and helps maintain accurate stock levels.

Traceability

- Bar-coding: A scanning technology that allows for greater efficiencies in inventory look-up activities compared to systems that require manual part # entry.

- Serial number tracking: Allows for identification of the particular unit being sold/repaired/built etc.

- Lot number tracking: Allows for inventory tracking of groups of inventory and is often used for management of inventory that cannot be easily tracked as individual units.

- RFID tracking: Radio Frequency Identification. Accurately track items via microchips. RFID readers send radio waves and interpret frequencies into inventory data.

Advanced Inventory Management Software Features

- Kitting: Allows for multiple items to be combined to form another item.

- Pricing management: Allows for the association of price information with particular SKUs and can be used for more sophisticated pricing tasks, such as determining discount eligibility.

- Bill of materials: Lists material quantities and assemblies needed to manufacture an end product. Can be referred to as a "manufacturing recipe.”

- Inventory audit management: Helps reconcile inventory records with actual item stock counts.

- Color/size matrix: Minimizes the number of records required to track different product combinations that vary by color or size.

- Landed cost tracking: Looks at all costs associated with acquiring inventory (including shipping, duties, and related fees) to provide more accurate per-product costing.

- Unit of measure conversion: Handles standard conversions (eg, yards to meters, pounds to kilograms) as well as user-definable ones (pallets to cases), allowing for greater flexibility in item quantity tracking.

- Catchweight tracking: Provides a means of managing items that are tracked by one unit of measure (for example, packages or cases) but priced on the basis of weight (or another measurement).

- Back order tracking: Provides the ability to reserve incoming stock to meet the obligations of pending customer orders.

- Inventory hold management: Reserves existing stock to fill customer orders and helps prevent duplicate inventory promises, which can cause customer satisfaction issues and negatively affect customer retention.

- Replenishment thresholds (reorder points): Provide a means of systematically specifying the stock count level, which should signal re-order of the inventory item; can be connected with system alert/notification capabilities to ensure that out-of-stock situations do not occur.

- Quality metrics: Track information about the condition of individual inventory items, which can be used in supplier selection and other inventory-related decisions.

Benefits

The top benefits of implementing an inventory tracking software include:

Managing Your Products for Sales Success

Maintaining the right amount of stock is critical to meeting customer demands. But it’s not as easy as just having extra stock on hand. Over-purchasing stock can tie up valuable cash resources, incur warehousing expenses, and create losses on items with sell-by restrictions. Inventory management software provides comprehensive control of your products, including pricing lists, item counts, and location tracking.

Maintain Accurate Stock Counts

No matter the size of your company, you need to track inventory and sales accurately to maximize your profitability. When you automate your inventory, you’ll always have an up-to-date item count that lets you quickly determine which products are selling and which are not. By understanding sales trends, you can accurately plan your purchases to lower the costs of storing physical items. Stocking the right items at the right time is one of the main factors in ensuring you are meeting customer demands and enhancing your ability to increase revenues.

Save Time By Automating Inventory Tasks

Inventory management solutions offer a variety of tools for automating time-intensive tasks related to keeping track of stock. Bar-coding and RFID-compatible options are available to allow you to gather individual item information by scanning the item rather than manually keying in data. Additionally, inventory management solutions can store precise information on item locations, so you always know where to find your products and don’t lose time locating stock in your POS system.

What Type Does Your Business Need?

To determine which solutions to look into, you may look at options intended for your size of business:

New Buyers and Small Businesses

Most basic accounting software will have a straightforward inventory tool, primarily for inventory costing and simple stock count tracking. Most small businesses will look to have inventory as a feature included with accounting software or POS systems, rather than purchase an expensive stand-alone.

Existing Users Desiring Functions Beyond Basic Inventory Management

Growing businesses with substantial inventory often seek standalone solutions that integrate with the financial systems they already use for purchase orders. Manufacturers need a bill of materials feature that allows them to replicate lists for goods they frequently produce. Distributors require systems that can track their assets and automatically reorder materials as their stock levels decrease.

Large Companies

Enterprise-level organizations will typically have inventory solutions included in their enterprise resource planning (ERP software) as part of a fully integrated software solution. They may also manage multiple warehouses, in which case a warehouse management system (WMS) may be the better fit for them.

If you’re looking for a more specific piece of inventory software, these related solutions may be worth looking into:

Pricing Guide

The cost of inventory management software will depend on the following:

- Number of users

- Deployment method

- Number of warehouses

- Level of inventory being tracked (total SKUs)

- Any needed implementation or training

Here’s a breakdown of what you can expect to pay and what systems will fit your budget based on your company size:

| Tier | Company Size | Average Yearly Cost | Examples |

|---|---|---|---|

| Low-Tier | 1–25 employees | $2,000–$10,000/year | Zoho Inventory, SOS Inventory, Cin7 Core, Ordoro |

| Mid-Tier | 25–150 employees | $10,000–$50,000/year | Acctivate, Fishbowl, Finale Inventory, Cin7 Omni, TradeGecko (QuickBooks) |

| High-Tier | 150–500 employees | $50,000–$100,000/year | NetSuite WMS, Microsoft Dynamics 365 SCM, Infor CloudSuite, Manhattan Active |

| Enterprise | 500+ employees | $150,000+ per year | SAP EWM, Oracle Fusion SCM, Blue Yonder Luminate, Manhattan Associates WMS |

To figure out an honest price quote for you, software vendors will usually ask the following critical questions:

- What do you need?

- How big is your inventory?

- How many employees do you have?

For example, a simple inventory system designed for managing just a few shelves in a small ice cream shop wouldn’t be suitable for a large company that requires management across five warehouses and handles over 250,000 different SKUs.